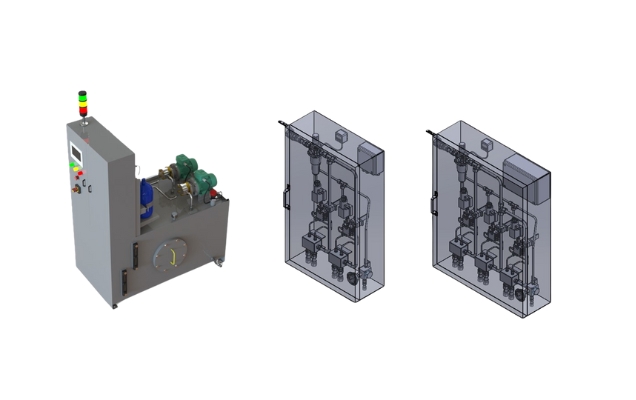

STEON™ Air-Oil Systems are engineered to deliver precise, continuous lubrication for high-speed and high-performance machinery. By combining measured amounts of oil with a controlled stream of compressed air, these systems ensure optimal lubrication while keeping components cool, clean, and operating at peak efficiency.

Designed for the most demanding industrial applications, our Air-Oil Systems reduce friction, prevent overheating, and extend component life helping you minimize downtime and lower long-term maintenance costs.

A central pump meters exact quantities of lubricant, which are then mixed with compressed air in specialized injectors or mixing valves. This air-oil mixture is carried through small-diameter tubing directly to the lubrication points. The continuous airflow not only delivers the oil precisely where it’s needed but also helps purge contaminants and maintain a clean lubrication path.

STEON™ Air-Oil Systems are ideal for high-speed bearings and spindles in steel and aluminum mills, paper manufacturing machinery, CNC machine tools, gearboxes, chain drives, and other precision or heavy-duty equipment.

At STEON, we don’t just supply lubrication systems we deliver engineered solutions built on decades of experience, innovation, and industry insight. Here’s why leading industries trust STEON for their Single Line Progressive Systems:

With years of hands-on experience in industrial lubrication, STEON™ understands the challenges across different sectors. Our systems are backed by deep technical knowledge and real-world applications that ensure performance and reliability.

From initial consultation and system design to installation, training, and after-sales service, STEON™ provides complete support throughout the lifecycle of your lubrication system. We’re your long-term partner, not just a supplier.

While we serve clients around the world, our support is always local. With a network of service professionals and partners, we ensure fast response times and on-site assistance when you need it most.