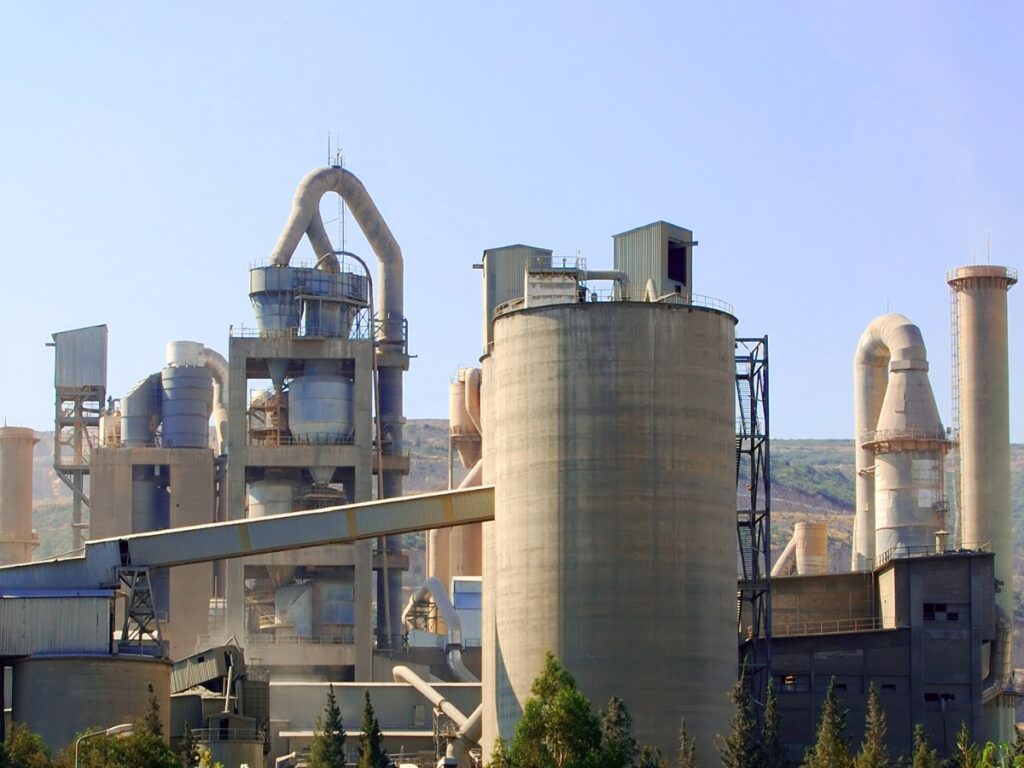

In the cement industry, continuous operation, reliability, and efficiency are critical. From rotary kilns, ball mills, and crushers to conveyors, fans, and grinding equipment, every moving component bearings, open gears, trunnions, chains, and hydraulic drives works under heavy loads, dusty environments, high temperatures, and extended duty cycles. Without proper lubrication, wear accelerates, energy efficiency drops, and unplanned downtime can disrupt production schedules, driving up costs and reducing plant output.

Manual greasing in cement plants is labor-intensive, inconsistent, and often impractical given the scale and operating conditions. STEON’s automated lubrication systems deliver the precise amount of lubricant to critical points exactly when and where it’s needed—without shutting down equipment. With programmable controls and optional remote monitoring, maintenance teams can track performance and system health in real time, ensuring reliable operation across the entire plant.

A STEON-engineered lubrication solution helps extend equipment life, maintain process efficiency, reduce unplanned stoppages, lower total maintenance costs, and keep cement production running at peak capacity kiln after kiln, shift after shift, year after year.

Our team of experts is ready to craft a solution tailored precisely to your needs.

In cement production, every machine in the plant is essential to meeting output targets. From rotary kilns, ball mills, and crushers to conveyors, fans, and clinker coolers, each asset must operate at peak performance to handle heavy loads, long duty cycles, and some of the harshest industrial environments. Constant exposure to heat, dust, vibration, and continuous operation pushes bearings, open gears, trunnions, and drive systems to their limits.

That’s where STEON lubrication technology delivers the advantage. Our intelligent, automated systems apply the precise amount of lubricant at exactly the right time—protecting every moving part, even under extreme cement plant conditions. With real-time monitoring and control, you can detect wear before it becomes costly, prevent unplanned stoppages, and keep production running at maximum efficiency—kiln after kiln, shift after shift.

Choosing Steon Automatic Lubrication Systems for your machine tools ensures reliable performance, reduced maintenance, and maximized productivity. Steon’s advanced systems deliver precise lubrication to critical machine parts, significantly lowering friction and wear

Our automated systems target the most sensitive moving parts of your tools, helping you maintain tolerance accuracy and surface quality.

Minimize emergency repairs and regular manual interventions, lowering overall maintenance expenditure.

Consistent lubrication decreases friction and wear, ensuring your investments deliver long-term value.

Less downtime means more output let your machines focus on what they do best.

Optimal lubrication reduces energy consumption and lubricant waste, advancing your green manufacturing goals.