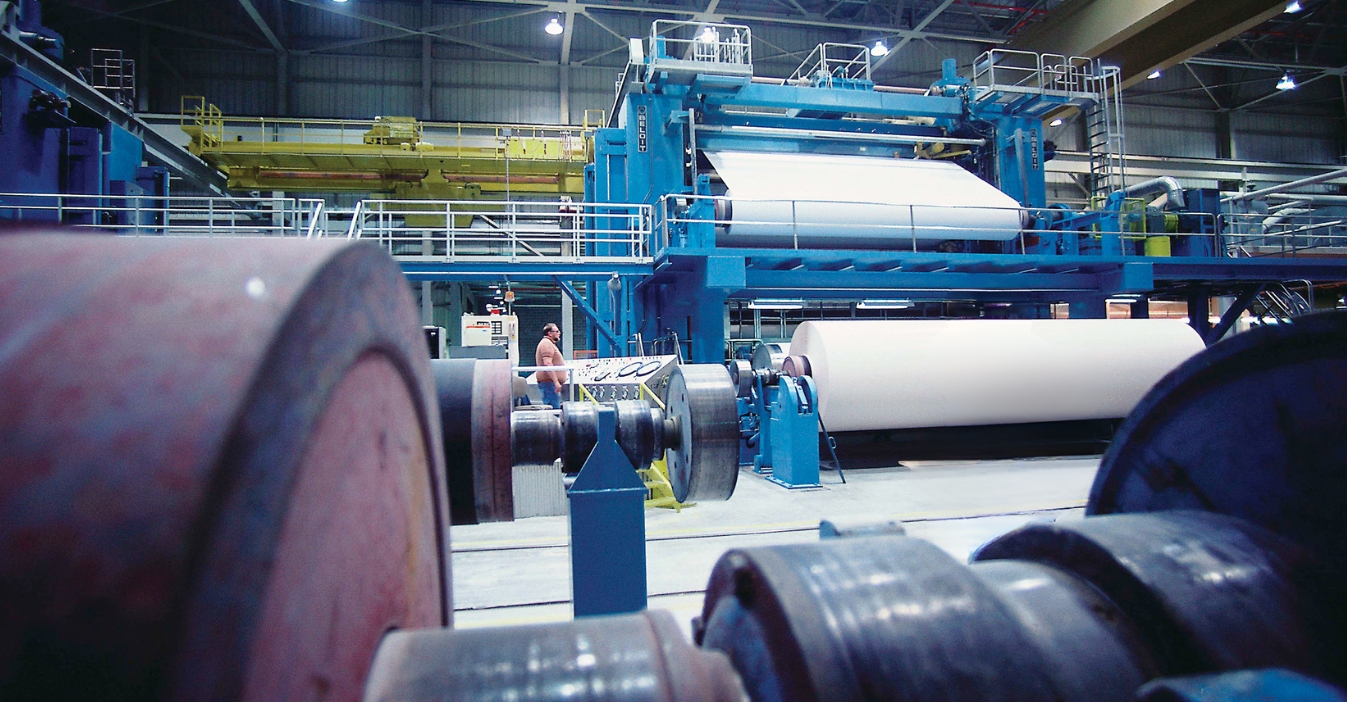

In the pulp & paper industry, continuous operation and reliability are non-negotiable. From pulp refiners and press rolls to drying cylinders, calenders, and rewinders, every moving component bearings, gears, felt rolls, chains, and couplings works under high loads, high moisture, elevated temperatures, and relentless operation. Without proper lubrication, wear accelerates, friction increases, and unexpected breakdowns bring production to a halt.

Manual greasing is not practical for modern, large-scale paper machines that run 24/7. Automated lubrication systems with programmable control and remote monitoring deliver the precise amount of lubricant to the exact point of need while the machine is running reducing the risk of under- or over-lubrication.

A STEON engineered lubrication solution not only extends equipment life but also minimizes unplanned downtime, reduces maintenance labor, optimizes energy efficiency, and ensures consistent product quality from reel to reel. This is how mills stay competitive shift after shift, roll after roll.

Our team of experts is ready to craft a solution tailored precisely to your needs.

In pulp & paper production, your machinery is the backbone of the mill. From pulp refiners and press rolls to dryers, calenders, and rewinders, these systems must run continuously to meet output and quality demands. But high moisture, heavy loads, heat, and non-stop operation push every component—bearings, gears, felt rolls, and chains—to their limits.

That’s where STEON™ lubrication technology makes the difference. Our intelligent systems deliver the precise amount of lubricant exactly when and where it’s needed, keeping critical moving parts protected in the harshest operating conditions. With real-time monitoring, you can stay ahead of wear, prevent costly unplanned downtime, and keep your mill running at peak performance—day after day, roll after roll.

Choosing Steon Automatic Lubrication Systems for your machine tools ensures reliable performance, reduced maintenance, and maximized productivity. Steon’s advanced systems deliver precise lubrication to critical machine parts, significantly lowering friction and wear

Our automated systems target the most sensitive moving parts of your tools, helping you maintain tolerance accuracy and surface quality.

Minimize emergency repairs and regular manual interventions, lowering overall maintenance expenditure.

Consistent lubrication decreases friction and wear, ensuring your investments deliver long-term value.

Less downtime means more output let your machines focus on what they do best.

Optimal lubrication reduces energy consumption and lubricant waste, advancing your green manufacturing goals.